With the rapid advancement of technology, the biopharmaceutical industry is facing unprecedented opportunities. However, alongside the industry’s swift expansion, challenges such as energy consumption and environmental issues are becoming increasingly prominent. Achieving green and sustainable development within the biopharmaceutical sector has become one of society’s critical priorities.

As a leading domestic green and low-carbon professional service provider with over a decade of deep industry cultivation, Junye Low Carbon leverages its outstanding expertise and extensive practical experience to deliver full lifecycle green and low-carbon solutions for numerous biopharmaceutical enterprises. This supports the industry’s progression toward a new stage of high-quality development.

Today, through a series of compelling collaborative case studies, we will fully demonstrate Junye Low Carbon’s profound experience and exceptional contributions in serving the biopharmaceutical industry. Together, we will witness how green and low-carbon practices empower this sector, ushering in a new chapter of sustainable development.

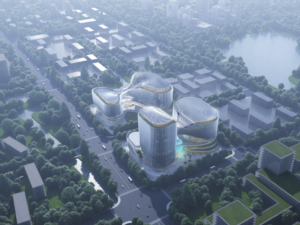

01. Chia Tai Tianqing Global R&D Headquarters

Service Provided: LEED BD+C Gold Certification

The Chia Tai Tianqing Global R&D Headquarters is dedicated to establishing an internationally leading green R&D center. The project employs passive design strategies, with photovoltaic roof systems installed on four buildings. It fully utilizes the architectural forms and structures of plazas, surrounding corridors, and rooftops to create multi-level, highly integrated landscape spaces. Additionally, the project provides priority and green vehicle parking, along with dedicated bicycle parking and shower facilities.

In terms of water resource management, the project implements stormwater management practices and reduces environmental impact through heat island mitigation (using high-reflectance surfaces) and light pollution control (for outdoor lighting). It has completed the commissioning process for mechanical, electrical, plumbing, and renewable energy systems and components. A monitoring-based protocol has been established to evaluate the performance of energy and water consumption systems.

Energy usage (electricity, water, gas, etc.) is categorized and sub-metered, employing remote digital metering instruments capable of hourly, monthly, and yearly data analysis. The comprehensive application of these green technologies makes the Chia Tai Tianqing Global R&D Headquarters a benchmark for green building within the biopharmaceutical industry.

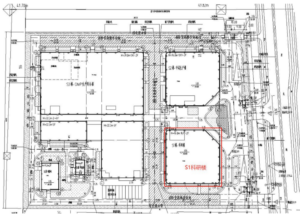

02. Yunji Pharmaceutical Southwest Headquarters and Pharmaceutical Logistics “Huijing Port” Phase I

Service Provided: Three-Star Green Industrial Building Design Consulting and Certification

The Yunji Pharmaceutical Southwest Headquarters and Pharmaceutical Logistics “Huijing Port” Phase I project is located in Xindu District, Chengdu. It is dedicated to creating green industrial buildings that achieve a balance between high operational efficiency and environmental friendliness. During the design process, Junye Low Carbon implemented a series of green industrial building technologies to significantly enhance the project’s sustainability. For example, 10% of parking spaces in the above-ground lot are equipped with EV chargers to encourage green commuting. Additionally, no less than 80% of sanitary fixtures meet the water efficiency Grade 1 standard, with the remainder achieving Grade 2 or higher, leading to substantial water conservation.

These measures not only considerably reduce the project’s operational costs but also provide valuable reference experience for the green transformation of the pharmaceutical logistics industry.

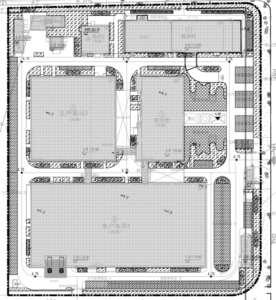

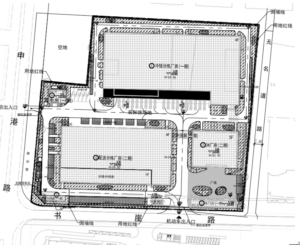

03. International Biopharmaceutical Innovation Center

Service Provided: Guangdong Provincial Three-Star Green Building Design and Certification Consulting

In this project, Junye Low Carbon actively implemented green building principles by integrating multiple energy-saving, water conservation, and energy efficiency enhancement measures. The project utilizes high-efficiency cooling/heating source equipment, high-efficiency fans, and pumps to reduce energy consumption from the source. Through the installation of remote water meters and an energy consumption monitoring system, precise management of building energy use is achieved, ensuring maximum energy efficiency.

For water resource management, the project incorporates a rainwater reuse system and employs high-efficiency water-saving fixtures. Landscaping irrigation utilizes water-saving methods, significantly reducing overall water consumption. The comprehensive application of these green technologies effectively improves the project’s resource utilization efficiency and environmental sustainability, providing a solid green foundation for innovation in the biopharmaceutical industry. Notably, the green building design target for Plot 3 is Three-Star level.

The project aims to create a green innovation center integrating diverse functions including offices, a hotel, and factory buildings.

04. Mabury Biopharmaceutical Research Building

Service Provided: National Two-Star Green Building Design Consulting and Certification

Located in Jiangsu Province, this project involved Junye Low Carbon implementing a range of green building technologies focusing on the building envelope, indoor environmental control, and safety. For example, the airtightness of exterior doors and windows meets or exceeds Level 6 as specified in GB/T 31433-2015, and the building curtain wall airtightness meets or exceeds Level 3, effectively reducing building energy consumption.

Simultaneously, personnel safety protection measures were adopted, and a vehicle-pedestrian separation system was implemented. The pedestrian and bicycle traffic systems are equipped with sufficient lighting, enhancing traffic safety and convenience within the campus. Major functional rooms are outfitted with individually controllable thermal environment regulation devices to ensure indoor comfort. Furthermore, an interlinked carbon monoxide concentration monitoring system was installed in the underground garage to ensure air quality in that space.

These measures collectively provide researchers with a healthy, efficient, and sustainable working environment, effectively aiding in talent attraction and retention.

05. Innovent Biologics Global R&D Center

Service Provided: Shanghai Two-Star Green Building Certification

Located in Shanghai’s Minhang District, the project aims to achieve the Shanghai Two-Star Green Building standard, providing a green and efficient platform for biopharmaceutical research and development. For this project, Junye Low Carbon prioritized building energy efficiency and occupant comfort. All fixed surfaces in common areas were fully finished with tiling or painting, and basic equipment for plumbing, HVAC, electrical, and ventilation systems were completely installed, ensuring high construction quality.

Particularly noteworthy is that the unit air volume power consumption of fans in the ventilation and air conditioning system is 20% lower than the requirement stipulated in the current Shanghai engineering construction code *”Energy Saving Design Standard for Public Buildings” DGJ 08-107*. This represents a significant reduction in energy consumption and fully demonstrates Junye Low Carbon’s professional expertise in the application of energy-saving technologies.

06. Chengdu Kanghua Biological Products Co., Ltd. New Vaccine Production Center

Service Provided: Sichuan Provincial Two-Star Green Building Design and Certification Consulting

The project utilizes ready-mixed mortar, ready-mixed concrete, and prefabricated building components to reduce resource consumption and environmental pollution during construction. For energy management, it employs hierarchical and categorical metering devices with remote transmission capabilities, enabling refined energy management. In terms of water resource utilization, the project incorporates Grade 2 water-saving fixtures, a rainwater collection and reuse system, and a water-saving irrigation system.

Furthermore, the project is equipped with high-efficiency HVAC systems, fans, pumps, an automatic control high-efficiency lighting system, high-efficiency transformers, motors, and luminaires. These measures comprehensively enhance the building’s energy efficiency, providing a green and efficient operational foundation for vaccine production.

07. Jianjin Pharmaceutical Biological Workshop

Service Provided: National Two-Star Green Building Design and Certification Consulting

Aiming for the National Two-Star Green Building standard, this project is dedicated to creating a biopharmaceutical production workshop that equally prioritizes ecology and manufacturing. By implementing distinctive ecological facilities that integrate well with the landscape—such as permeable pavement and sunken green spaces—the project effectively captures, retains, and reuses stormwater runoff.

These measures not only significantly alleviate pressure on municipal drainage systems and enhance the efficiency of water resource recycling but also achieve an organic unity between ecological functionality and aesthetic landscape outcomes.

08. Qingdao Biopharmaceutical Collaborative Innovation Center

Service Provided: National Two-Star Green Building Design and Certification Consulting

The project aims to achieve the National Two-Star Green Building standard, dedicated to establishing a highland for biopharmaceutical research and innovation. It integrates multiple green building technologies, comprehensively enhancing the project’s safety, energy efficiency, and sustainability.

The design employs an open and flexible spatial layout. Grade 2 water-saving fixtures, PPR water supply pipes, and flame-retardant copper core cables with low smoke and low toxicity are selected to ensure water and electricity safety and efficiency. Through the deployment of a Building Automation System (BAS), real-time monitoring, intelligent management, and energy-saving optimization of electricity, water, and heating/cooling energy consumption are achieved.

The project is equipped with three high-performance magnetic levitation centrifugal chillers, whose cooling energy efficiency exceeds the Shandong provincial standard by over 60%. Furthermore, the project prioritizes the use of green building materials, with reusable and recyclable materials accounting for 10.34% of the total building material weight. This effectively promotes resource conservation and environmental friendliness, providing a green and efficient platform for collaborative innovation in the biopharmaceutical industry.

09. Laoshan District Biopharmaceutical Health Industry Park (Phase I) Medical Rehabilitation Aggregation Center

Service Provided: Shandong Provincial Two-Star Green Building Design and Certification Consulting

For this project, Junye Low Carbon adopted comprehensive green building technologies across multiple dimensions, including safety & durability, health & comfort, convenience, resource conservation, and environmental livability. The implemented strategies encompass:

Passive Design Strategies: Natural ventilation and daylighting.

Outdoor Environmental Quality Assurance: Provision of public activity spaces, pre-analysis of acoustic and wind environments, and heat island mitigation.

Indoor Environmental Quality Control: Fresh air systems, indoor environmental monitoring, and sound insulation design.

Enhanced Safety Performance: Anti-slip, anti-fall, and anti-pinch designs.

Energy Efficiency: Utilization of high-efficiency cooling/heating sources and implementation of HVAC energy-saving strategies.

Water Conservation Measures: Application of water-saving sanitary fixtures, water-efficient irrigation, and use of non-traditional water sources.

Waste Management: Implementation of waste sorting systems.

Intelligent Building Systems: Design of smart building management systems.

The integrated application of these technical measures aims to achieve health, livability, energy saving, and carbon reduction throughout the building’s entire lifecycle, providing strong support for the green development of the medical rehabilitation industry.

10. GE Biotech Park Phase I Project

Service Provided: Industrial One-Star Green Building Design and Certification Consulting

This project aims to establish a large-scale, standardized pharmaceutical production base and pilot platform, expanding across the entire industry chain by leveraging GE Healthcare’s technology. Junye Low Carbon actively implemented green building principles in this project by integrating multiple energy-saving, water conservation, and energy efficiency enhancement measures.

The project utilizes a high-performance building envelope, including roofing extruded foam insulation panels and rooftop greenery on sections of the roof to effectively reduce heat gain. It employs high-efficiency cooling/heating source equipment, high-efficiency fans and pumps, with precision air conditioning systems installed in laboratories within the complex.

For electrical lighting, the project uses high-efficiency fluorescent lamps, metal halide lamps, or other energy-saving lights (e.g., T5 tri-phosphor fluorescent lamps with energy efficiency Grade 2). All fluorescent fixtures are equipped with electronic ballasts and built-in reactive power compensators, achieving a power factor of 0.9 or above.

Additionally, measures such as rooftop greenery, retention ponds, and permeable pavement have been implemented to reduce site stormwater runoff.

11. Mengyang Pharmaceutical Group Headquarters and Innovative Drug R&D Production Base

Located in Shanghai, the Mengyang Pharmaceutical Group Headquarters and Innovative Drug R&D Production Base project is guided by the sponge city concept. It aims to naturalize the regional hydrological cycle and effectively manage stormwater runoff and pollution through ecological technologies.

For this project, Junye Low Capital fully utilized green spaces such as landscapes and gardens. Through meticulous soil replacement, plant selection, and hydrological design, a distributed, small-scale source control system was constructed. This system not only effectively intercepts and purifies rainwater runoff but also enables the hydrological cycle of the developed area to closely mimic its natural state, significantly enhancing the region’s ecological resilience and environmental quality.

12. Hepalink Biopharmaceutical R&D and Manufacturing Base

Located in the Pingshan New District of Shenzhen, the Hepalink Biopharmaceutical R&D and Manufacturing Base is dedicated to creating an eco-friendly environment for research, development, and manufacturing.

In this project, Junye Low Carbon implemented various sponge city technologies, including permeable pavement, sunken green spaces, and rainwater collection barrels. These measures establish an efficient stormwater management system that not only effectively mitigates urban flooding risks but also promotes the recycling and reuse of water resources.

13. Sinopharm Biopharmaceutical Industrial Park

Located in the Songjiang Economic and Technological Development Zone of Shanghai, this project also adopts the sponge city development objective, aiming to achieve harmonious coexistence between ecology and industry.

For this project, Junye Low Carbon utilized green spaces such as landscapes and gardens, combined with soil replacement, strategic plant selection, and hydrological engineering design, to construct a decentralized, small-scale source control system. These measures are designed to effectively manage stormwater runoff and pollution, allowing the hydrological cycle of the developed area to approximate its natural state as closely as possible. This approach fulfills the planning goals for green infrastructure and provides an ecological guarantee for the sustainable development of the biopharmaceutical industrial park.

14. Sansure Biotech High-Performance Medical Device Intelligent Manufacturing Industrial Park

Guided by the sponge city concept, this project is dedicated to creating an eco-friendly intelligent manufacturing base. Key sponge city measures implemented include sunken green spaces, rain gardens, and permeable pavement.

Roof rainwater is disconnected from downspouts and directed outdoors, channeled into nearby sponge facilities. Site rainwater is guided via road slopes or grass swales to rainwater retention facilities, where it is stored, conveyed, and infiltrated. Additionally, the substrate absorbs and stores moisture, effectively reducing rainwater flow velocity, delaying peak runoff times, and lowering discharge intensity.

Collectively, these measures establish an efficient stormwater management system that not only mitigates urban flooding risks but also promotes the recycling and reuse of water resources.

15. Maikang Biotechnology Novel Vaccine R&D and Industrialization Project (Phase I)

This project employs comprehensive sponge city technologies, including rain gardens, sunken green spaces, grass swales, permeable pavement, and rainwater reuse systems. Through these measures, it has achieved the targets of ≥90% initial rainfall collection and treatment rate and ≥2% rainwater resource utilization rate.

This approach not only effectively controls stormwater runoff pollution and enhances water resource efficiency but also provides a safe and environmentally sound site guarantee for the research, development, and production of novel vaccines, while continuously contributing to urban flood mitigation.

16. Yifan Pharmaceutical International Innovation Center

The project effectively controls stormwater runoff and stores water resources through the implementation of permeable pavement and retention ponds. The permeable pavement enhances ground infiltration, reducing rainwater discharge, while the retention ponds collect rainwater for non-potable uses such as landscape irrigation, achieving water resource recycling.

These measures not only align with sponge city construction requirements but also contribute to the project’s overall energy conservation and emission reduction goals, demonstrating Junye Low Carbon’s professional capability in integrating multiple green standards. The project integrates three green standards—One-Star Green Building, Sponge City, and Energy-Efficient Design—aiming to establish an internationally leading innovation center.

17. Medicilon Northwest Shanghai Biopharmaceutical R&D Innovation Industrial Base

The project aims to establish a green industrial base integrating research, development, and innovation. It employs a variety of sponge city technologies, including permeable pavement, sunken green spaces, interception facilities, and a rainwater harvesting system.

The permeable pavement increases surface infiltration and reduces stormwater runoff. Sunken green spaces and interception facilities detain and purify rainwater. The rainwater harvesting system enables the storage and reuse of collected water.

Together, these measures form an efficient stormwater management system that effectively controls runoff pollution, improves water resource utilization efficiency, and provides a green and environmentally friendly site for biopharmaceutical R&D and innovation.

18. Chongqing Wangye Biopharmaceutical (Phases I & II)

Located in Chongqing and developed in two phases, the project aims to establish an eco-friendly biopharmaceutical base through sponge city construction. Rain gardens have been implemented within public spaces and centralized green areas of the project site. By managing surface runoff and utilizing permeable pavement, surface flow is effectively reduced. Additionally, stormwater regulation and storage facilities, including retention ponds, have been reasonably deployed to enable the collection, storage, and reuse of rainwater.

The integrated application of these sponge city technical measures effectively helps mitigate urban flooding risks and promotes the recycling of water resources.

19. Luoxin Pharmaceutical Health Industry Park

Located in Chengdu, this project saw Junye Low Carbon implement a range of comprehensive green building measures. These included selecting Grade 1 water-saving fixtures and Grade 2 energy-efficiency water supply equipment, implementing separate water supply systems and segregated drainage for wastewater of different qualities, and employing water-efficient sprinkler irrigation for landscaping.

Regarding energy conservation, a high-efficiency lighting system featuring zoning, timers, and motion sensors was installed in public areas. Energy consumption monitoring devices and systems were also put in place to enable real-time monitoring and statistical analysis of the building’s energy use.

Together, these measures comprehensively enhance the building’s resource utilization efficiency and sustainable operational performance, providing solid support for the green development of the pharmaceutical health industry park.

With over 14 years of deep industry experience, Junye Low Carbon has not only accumulated extensive technical expertise but has also established itself as an indispensable partner for biopharmaceutical companies on their path toward green transformation and sustainable development.

Moving forward, Junye Low Carbon will continue to uphold its spirit of innovation, constantly exploring cutting-edge technologies to write a new chapter of harmonious coexistence between health and the environment for the nation, families, and society.